OUR PRODUCTS

We offer a wide range of services, from consultancy to providing engineering design and fabrication, manufacturing, supply and commissioning of products and services related to Oil & Gas and Marine Industry for the territory of Malaysia especially for the home grounds of East Coast Malaysia.

PRODUCT DETAILS

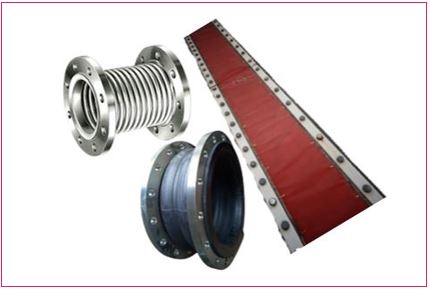

METAL expansion joint

Manufacturing size range is from 50mm up to 6000mm, in various configurations (etc. : tied, hinged) and shape such as rectangular, circular, thick wall and cold spun.

Material available is Stainless Steel, Incoloy, Inconel, Hastelloy, Titanium and Monel.

Designed to EJMA 10th Edition or ASME as required.

Usage: to carry various media including steam, emission gases, water, acid, alkalis and hydrocarbon.

TYPES

Single Expansion Joint

Universal Tied Expansion Joint

Pressure Balanced Expansion Joint

Double Hinged Expansion Joint

Gimbal Expansion Joint

Double Hinged Expansion Joint

Single Tied Expansion Joint

fabric expansion joint

Factory is equipped with an Overhead Crane with 5 tons capacity, Fabric Molding, Special Splicing, and a special table for Fabric Expansion Joint assembling to ensure the quality of our products.

Additionally we also commit to provide the best services by offering complete installation with our manpower consists of highly skilled Personals with an extensive field of experience and a solid teamwork.

Single Layer : one or more reinforcement plies with coatings of elastomers or fluoroplastics to form a homogenous material.

Composite Layer Type : comprises of different layers of materials, which are glued, knitted or bolted together on its flange clamp area. This gives Composite layer type a unique advantage as each layer of materials has its own characteristics and functionalities.

AWS and ASME as a guidance for each step of the production flow. In addition, we also adopt the Fluid Sealing Association (FSA) Technical Handbook for Ducting System for Non-Metallic Expansion Joint for its production process.

Product Range

High quality Expansion Joint for low temperature

Material: Single or Multilayer Construction

Temperature: 50 ~ 300 Deg. C (max)

Pressure: 0.3 barG

Multiple layer & Versatile Expansion Joint

Material: Multilayer Construction

Temperature: 400 Deg. C (max)

Pressure: 0.3 barG

Adaptable, Resistance & Versatile Expansion Joint

Material: Multilayer Construction

Temperature: 600 Deg. C (max)

Pressure: 0.3 barG

Extreme condition, custom made Expansion Joint

Material: Multilayer Construction

Temperature: 1000 Deg. C (max)

Pressure: 0.3 barG

rubber expansion joint

We offer a wide variety of design to meet various piping system requirements such as:

• Pressure

• Temperature

• Movement

• Stiffness

• Fluid resistance

• End Connection with mating pipe flange etc.

Inspection, Quality Control & QA Management

Strict inspection and testing procedures combined with rigorous standard for all materials and assemblies at every stage of manufacture to maintain high quality in the finished products.

Valve parts

We offer a wide variety of valves parts to cater your requirement and needs.

Structure: Ball valve, Gate valve, Plug valve, Globe valve, Butterfly valve, Swing Check valve and many more

Material: Gray iron, Ductile Iron, Stainless Steel

Production process: Automatic molding line, resin sand, green sand, shell casting, pre-coated sand.

Surface treatment: Automatic line spray, general spray paint, primer, anti-rust oil, electrophoresis

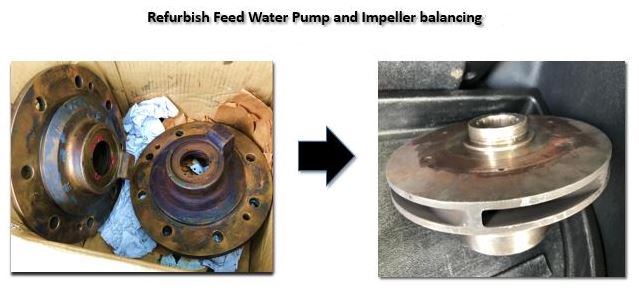

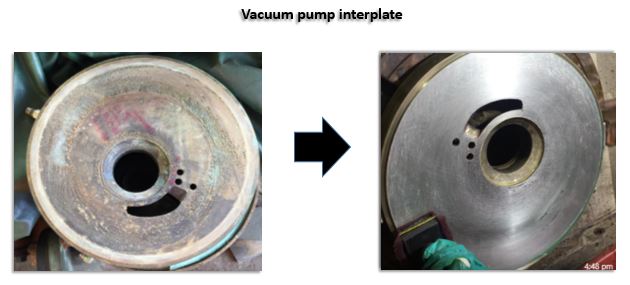

metal rebuilding

We also offer metal rebuilding services for those who are in a low budget.

This method is cost saving efforts while being environmentally friendly with our biodegradable technique.

Metal wears down in aggressive environments, resulting in costly repairs and the loss of valuable time. With our new improved technology for metal rebuilding, this solution are designed to counter this impact.

Benefit for you:

• Cheaper option • Less time needed • Improve the performance • Extending the useful life

strainer & filter

Simplex Strainer

Function: suited for transferring fluids at a higher velocity

Y-Strainer

Function: remove unwanted particles from steam, gas, or liquid using a straining element typically made of wire mesh

T-Strainer

Function: suited for transferring fluids at a higher velocity

Bucket Strainer

Function: protect equipment from damage caused by unwanted debris that may be in the pipeline protect

hoses

Flexible Metal Hose

A metal hose is made of four basic components:

• Corrugated tubing

• Braid

• Braid collars

• End-fittings

Interlock Hose

Ability to not contaminate the transferred product with any residue. When transferring abrasive materials, interlock hose has an advantage over softer hose.

Composite Hose

Benefits:

• Lightweight

• Highly Flexible

• Multi-purpose

• Safe

• Robust

• Long Shelf Life

• Versatile in manufacturer

• Relatively inexpensive

• Relatively quick to produce

gasket

Manufactures following standards API 6A and ASME B16.20.

Material available is SS304L, SS 316, SS 316L, SS304H, SS316H, SS321, SS410,Duplex 31803, Duplex 32205, Duplex 32750, Duplex 32760, Inconel 600,Inconel 625, Inconel 800, Inconel 825 & Monel.

Gasket Type:

1. Soft Cut - PTFE Gasket, Graphite Gasket, Rubber Gasket, Insulation Kit Gasket, Compressed Fiber Sheet Gasket (Non-Asbestos)

2. Semi-Metallic - Spiral Wound Gasket, Kamprofile Gasket, Jacketed Gasket

3. Metallic - Ring Joint Gasket (Style R, Style, RX, Style BX)

gLAND PACKING

We provide high-quality products to the world's leading industries, including oil and gas, construction and engineering, marine and offshore.

The type of gland packing is choose based on the designation of reducing leakage and sealing purpose for different application.

-> Environment friendly (Asbestos replacement)

-> Composition as per International Standard

-> International Standard Compliment BS 4371

Specification:-

Application: Chemical Resistant, Refiners, Pump, Valve, Piston

Medium: Water, Air, Steam, Mild Acid, Alkalis etc.

pH: 2 ~ 14

Max Temperature: 150°C ~ 600°C

Max Pressure: 20kgf/cm2 ~ 260kgf/cm2